Commercial Ice Maker Repair Dallas

Is your ice maker acting up, not making ice or leaking water? Call Refrigeration Techs now and we’ll send a technician to your location with a fully loaded truck to get your ice maker back up and running efficiently.

Choosing Refrigeration Techs ensures the correct repairs the first time, minimizing downtime and maintaining ice quality while repairing any underlying problems. We serve all of Dallas, TX for all commercial ice machine repairs, our job is not finished until our customer is fully satisfied.We specialize in service of all makes and models of commercial ice machines including; Hoshizaki ice maker repair, Scotsman ice maker repair, and Manitowoc ice maker repair. In this guide, we will try to help you diagnose and fix common issues quickly and learn more about what’s going on with your equipment.

CALL NOW! (214) 550-2628

Important Notes

- Regular maintenance of ice makers, including cleaning and filter replacement, is essential to prevent common issues and ensure high-quality ice production.

- Electrical failures in ice makers can sometimes be traced back to loose connections or faulty components.

- Refrigeration Techs is on call 24/7 for any ice machine repair in Dallas, TX.

Common Ice Maker Problems and Solutions

Commercial ice machines can have many issues some more preventable than others. One frequent issue is ice clumps forming in the ice bin, which can lead to leaks and operational problems. This can be caused by an unlevel ice maker, which causes melting ice to pool and leak, resulting in water damage. Keep your ice maker level and well-maintained to avoid this issue.

Common problems with ice makers include:

-

Accumulation of contaminants, which can affect the taste and quality of the ice produced.

-

Old ice cubes acquiring odors from the refrigerator, leading to unpleasant-tasting ice.

-

Growth of harmful bacteria, which can be prevented by regular cleaning to keep the ice safe for consumption.

-

Misalignment of the ice maker’s control arm, which can cause continuous production or a complete halt in ice production; correctly positioning the control arm resolves this problem.

Ice Machine Not Producing ice

When your ice maker isn’t producing ice as it should, diagnosing the issue is the first step. Consider the following:

-

One of the most common culprits is a defective water inlet valve, which may not provide sufficient water pressure for ice making.

-

Inspect the inlet valve, which controls water flow and can become clogged or damaged, leading to leaks.

-

Keep the water supply valve fully open to help maintain proper water pressure.

To maintain your ice maker and ensure proper ice production:

-

Check the water line for damage like cracks or kinks to prevent leaks.

-

Inspect and replace clogged water filters regularly, as they can significantly reduce ice production by restricting water flow.

-

Adjust the water fill level for the ice mold to resolve issues with ice size and production.

-

Perform regular filter inspections and replacements to keep your ice maker running smoothly.

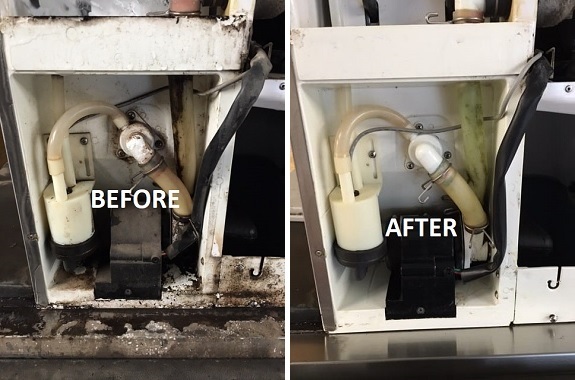

Commercial Ice Maker Cleaning

Regular maintenance is essential for the optimal performance of your ice maker. A maintenance schedule prevents problems, saves time and money, and ensures high quality ice. Commercial ice makers should be cleaned at least bi-annually, while those in high yeast areas, like pizza shops and bakeries, may need monthly cleanings to mitigate contamination risks.

To maintain ice quality and machine efficiency:

-

Regularly clean to prevent scale, mold, and slime accumulation, which can contaminate ice and pose health risks.

-

Change water filters as recommended by manufacturers.

-

Clean and tighten connections between the water line and the ice maker to help mitigate leaks and prevent scale buildup, ensuring optimal water quality.

Adhering to a maintenance schedule and keeping your ice maker clean ensures efficient operation and safe, high-quality ice. Call Refrigeration Techs today and we’ll dispatch a certified technician to your location and clean your ice machine in coherence with FDA requirements. This not only extends the lifespan of your appliance but also enhances its performance and reliability.

Call Now for Ice Machine Cleaning in Dallas, TX.

CALL NOW: (214) 550-2628

Other Services We Offer...

Walk In Cooler Repair

Need repair for your Walk In Cooler in Dallas Texas? We’re you’re guys. When you’re system goes down, theres no time to waste, don’t let your products spoil, give us a call now and get quality commercial refrigeration repair ASAP!

HVAC System Repair

When your HVAC system goes down on you in this Texas weather you need to act fast. In our 15+ years experience we’ve seen it all. From faulty compressors to refrigerant leaks, even faulty electrical, we have the knowledge and skillset to get your air conditioning system up and running in no time.

Walk In Freezer Repair

We understand how important a functioning Walk In Freezer is to your business, which is why we’re on call 24/7 in Dallas, ready to tackle the issue head on and have your system back and running in no time! Call us to schedule service today!

Commercial Refrigeration Installation

Whatever Commercial Refrigeration system you need installed in your kitchen or workspace we can do it! We have decades combined experience installing all commercial refrigeration systems including Walk In Freezer Installation, Walk In Cooler Installation, Ice Machines, Prep Tables, etc.. Give us a call to see how we can help.

Ice Machine Repair

If your Ice machine is not working properly, rest assured we’ve got your back. We offer service for all major ice machine brands including, Scotsman ice machine repair, Manitowoc ice machine repair, and Hoshizaki ice machine repair. Give us a call to schedule service anywhere in DFW.

Heating Installation

We also specialize in professional Heating Installation, and would be more than happy to discuss the needs of your space. Once we determine your needs, its our job to make sure we deliver on our promise to ensure your space stays comfortable and efficient, all year round. Our sky high standards for or services is why our customers continue to choose us for they’re air conditioning and heating services.

Frequently Asked Questions

What are the common issues with ice makers?

Common issues with ice makers often involve ice clumps, unlevel positioning, accumulation of contaminants, and misalignment of the control arm. Addressing these factors can ensure your ice maker operates efficiently.

How can I diagnose ice production issues?

To diagnose ice production issues, check the water inlet valve, water lines, water filters, and ensure temperature settings are correct. Identifying these components will help you resolve the problem efficiently.

What should I do if my ice maker is leaking water?

If your ice maker is leaking water, promptly turn off the water supply, check for cracks in the water lines, and ensure that drains are not blocked. Taking these steps will help prevent further damage and resolve the issue efficiently.

Why is professional installation important for ice makers?

Professional installation is crucial for ice makers to ensure optimal performance by properly addressing factors such as location, drainage, and ventilation, which prevents operational issues.

How often should my ice maker be cleaned?

To ensure optimal performance and hygiene, clean your commercial ice maker at least bi-annually, or monthly if located in high yeast areas such as pizza restaraunts or bakeries. Regular maintenance will prevent contamination and prolong the lifespan of the equipment.